BUILDING VENTILATION DESIGN

Nowadays, along with the emergence of the issue of the energy crisis, waste accumulation, lack of water and other environmental issues related to the growth of the human population who continues to build infrastructure for homes, factories, offices and others, the concept of green building is also growing.

Green building is a building that combines environmentally friendly products, starting from natural materials, concepts to save energy and water, or using recycled materials to utilize materials that cannot be decomposed or wasted. Design considerations or products that contribute to safety, and environmental health are also an important part of green building, one of the important considerations is the design of a good Heating Ventilation and Air-conditioner (HVAC).

Since the building will basically be inhabited by humans, and humans need good air to breathe, the design of good ventilation is quite essential. There is special emphasis on Indoor Environmental Quality (IEQ) on green building which must consider humidity control, air filtration, contamination control and of course ventilation.

There are various ways to get good ventilation in a building, while in green buildings the methods that are often used are natural ventilation, energy recovery ventilation, whole-house fans, energy-saving exhaust fans, and a combination of these methods to get the sufficient amount of ventilation. Whatever method is used; a green building designer must ensure that the combination of methods or equipment supports each other.

Nowadays, green building attracts the attention of many parties, because the concept is profitable in terms of energy use and sustainable for the environment globally, as well as in terms of business and marketing for building developers. Basically, ventilation systems in buildings in general and green buildings do not have a significant difference, but in the design of green buildings we expect the use of energy to be minimal.

To achieve adequate ventilation, sometimes passive airflow is insufficient and mechanical equipment such as fans or the use of an Energy Recovery Ventilator (EVR) system is required. Some of the standards that can be applied to mechanical whole-house ventilation are to meet ASHARAE 62.2 requirements with the following details:

- Whole-house mechanical ventilation system and controls installed to supply a certain rate of outside air (62.2 section 4), including ventilation limits at 62.2 section 4.5 (e.g. maximum 7.5 cfm/100 sq.ft) for “warm-humid” climates as defined by the IECC.

- Air transfer (used air in other rooms/ducting) should not be used.

- The air inlet is located at least 10 feet from the source of the contaminant.

- Air flow must be tested first to meet the design criteria of the manufacturer: for example, to check the air mass flow rate value is in accordance with the specifications.

Then, according to ASHARAE 62.2 section 5, local exhaust ventilation that leads out of the room must be installed in each bathroom and kitchen.

Regardless of the method used for ventilation, the important thing that must be considered for green building designers is to ensure that the methods used support each other and do not reduce each other’s performance, for example installing an exhaust fan with an air flow rate which after being tested has lower flow rate than the specification, this may happen if there is intervention from other tools installed in inappropriate locations.

Or maybe the installation of air inlets from blowers or fans whose flow is not evenly distributed throughout the room: there are areas with high local air velocity but there are also areas that are not touched by air circulation at all and many more.

To overcome these problems, analytical/manual calculations are sometimes not possible due to special building plans or new building types and there has never been a previous reference, one of the best and rapidly developing alternatives currently being used is to use computer computing methods to model the air flow, or temperature distribution in the room, or also known as Computational Fluid Dynamics (CFD).

Using the CFD method, we can model unlimited room models like whatever we want and the locations of tools such as fans, exhausts, inlets, blowers and others, even this method can also model natural convection flows by taking into account the buoyancy that occurs due to differences in density due to differences in air temperature.

Moreover, if needed, we can model the exterior of the building being blown by the wind to see how much air is entering the building and air passing through the building just like that.

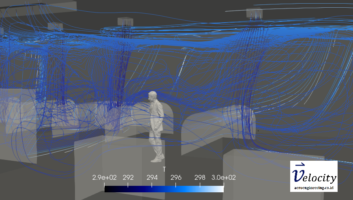

The pictures below are examples of a CFD analysis on a church building to see the characteristics of the air flow when passing through the building under various conditions (doors open/closed, windows open/closed, people inside/empty and so on).

The above simulations were made using openFOAM CFD software. Using the CFD software, we are able to get a more in-depth and specific insight into the designs we make.

>> CLICK HERE TO LEARN ON VENTILATION DESIGN USING CFD!

For those of you mechanical engineers who are improving their skills in the HVAC field, we also provide solutions, namely training on topics about HVAC with trainers who are very experienced in their fields to improve your skills and competencies as a professional engineer. Here are some training topics related to HVAC topics:

>>Training: Air conditioning and refrigeration: operation, installation and maintenance

>>Training: HVAC system commissioning

aeroengineering services is a service under CV. Markom with solutions especially CFD/FEA.

Leave a Reply

Want to join the discussion?Feel free to contribute!